Dominion Atlantic Railway Digital Preservation Initiative - Wiki

Use of this site is subject to our Terms & Conditions.

Category:Gypsum Trains

Gypsum Trains

The Windsor area contains extensive deposits of the mineral gypsum the main ingredient for plaster and drywall used for building construction. The large quantities of the Windsor deposits and short distance to American markets made the gypsum trade a growing bulk commodity for the Dominion Atlantic Railway soon after it was created. After the Apple Industry collapsed in the 1940s, gypsum became the DAR's largest commodity.

1891 to 1924

Large scale rail shipment of gypsum began in 1891 when a businessman from Staten Island, New York named Jerome Berre King (J.B. King) bought out the largest Windsor gypsum owner Edward Dimock as well as smaller quarry owners such as Thomas Mosher at Newport Station, expanding to control almost all the gypsum quarries around Windsor. King built a large fleet of barges, schooners and tugs called the Gypsum Packet Company to haul gypsum to his processing mills in Staten Island.[1] Several spurs from the DAR's mainline at Three Mile Plains and Newport ran to gypsum quarries. J. B. King also built short line railways to his own quarries. His largest quarry was at Wentworth. In 1891, the Wentworth Gypsum company was incorporated. In 1893 it was granted the right to build a railway for the mine. When the Midland Line opened in the early 1900s, rails were laid from the Wentworth quarry to the Midland mainline at Dimock's. A short line was also built in 1908 from quarries in the Avondale area to wharves at Newport Landing.[2]

Locomotive No. 4 "St. Croix" with a gypsum train at Moshers Quarry, Newport, date unknown.

Dumping gypsum into a schooner at Hantsport, Nova Scotia ca. 1900.

Dumping gypsum into a schooner at Hantsport, Nova Scotia ca. 1900.

Windsor Wharves with DAR gypsum cars and box cars in foreground and the L. A. Armstrong Apple Warehouse in background, pre-1914.

Gypsum Train being loaded, probably at Mosher Quarry in Newport hauled by DAR locomotive No. 25, circa 1920.

Gypsum Train from Mosher Quarry shunted by DAR locomotive No. 25 at Windsor Wharf, circa 1920.

Gypsum Train from Mosher Quarry shunted to load steamship at Windsor Wharves, circa 1920.

No. 21 "Fortuna" at Windsor with a gypsum train, circa 1921.

gypsum quarry spurs in the Windsor, Dimock's and Newport areas, from geological map, 1909.

1924 to 1947

In 1924, the J.B. King Company became the Canadian Gypsum Company and its Windsor Operations became the Fundy Gypsum Company.[3] They took over the Wentworth (Dimock's) quarries and used their own fleet of small quarry locomotives to move gypsum in the mines to loading facilities where DAR gypsum trains where loaded to move the loads to wharfside for ships. Gypsum from the Wentworth Gypsum Company's Wentworth (Dimock's) quarries was shipped from the Wentworth wharf on the Avon River when the facility was free of ice and from Deep Brook on the Annapolis Basin during the winter once Wentworth was iced up. During the summer, gypsum trains also ran to Deep Brook to build up gypsum stockpiles for winter shipments,[4] a movement captured in John MacIntosh's photo of No. 999 going from Windsor to Annapolis Royal with a Gypsum train. The DAR used CPR steel framed wooden sided "Big Otis" gondolas for this service.

Canadian Gypsum Company locomotives No. 6 and 7 and gypsum dump cars, unknown date.

Canadian Gypsum Company G.E. diesel locomotive and gypsum cars, circa 1947.

Canadian Gypsum Company G.E. diesel locomotive and gypsum mine cars, within the mine., circa 1947

Canadian Gypsum Company G.E. diesel locomotive and gypsum mine cars, within the mine, circa 1947.

Wentworth Gypsum mine at Dimock's, with Dock, circa 1940s.

DAR locomotive No. 530 with the Digby yard crew making the first gypsum dump at the new trestle in the Deep Brook gypsum terminal, June 18, 1940.

No. 999 leading a plaster train from Windsor to Annapolis Royal in August 1951. Note the DAR livery.

1947 to 2011

In 1947, a new facility was built at Hantsport that could load a cargo ship between tides ending the era of plaster trains to Wentworth and Deep Brook. The Deep Brook plant was converted to a storage facility and back up pier to handle the occasional shipment when Hantsport was closed. (The Deep Brook facility closed for good on October 11, 1954.)[5]

In 1956, the Canadian Gypsum Company built a new quarry at Miller's Creek in Mantua to supplement declining production at the quarry sites at Wentworth.[6] Both the Wentworth and Miller's Creek quarries shipped to the the Hantsport loading facility with the CPR's old Big Otis gondolas. However in 1963, a fleet of 75 steel gypsum cars unique to the DAR arrived, the 352900 gondola series. Usually organized into three consists of 25 cars each they ran as unit trains from the gypsum mines to Hantsport.[7]

The two mines in Windsor area located on the Truro Spur that used to be the Truro Subdivision (Midland route); the smaller of the two is Wentworth (Fundy Gypsum Wentworth Dark Quarry) at Dimock, the other at Mantua (Fundy Gypsum Bailey Quarry) at Miller's Creek.

The lower grade gypsum was from Mantua and the better grade pure white gypsum was from Dimocks. The gypsum was used over the years in multiple applications from manufacturing cement and personal products to fertilizer for peanuts.[8]

The day used to start in Windsor on the track behind the station. The crew would lift about 20 loads out of one mine, take them to Hantsport and exchange them with a like number of empties, then head to the other mine in Windsor and for loading.

At Hantsport, Fundy Gypsum had a 44 tonner that took up to six loads down to the dumper at a time. They would load the Gypsum (in rock form) directly into a ship or store it if necessary if a ship was not yet in port for any reason.

The road crew made three round trips a day, that means if they loaded cars at Mantua in the morning, they would also load the last trip at Mantua and then next morning they would first load at Wentworth and finish the day there. The first mine run would alternate between the two mines.

There are about four hours when the tide is high enough to float the ship and load, Fundy Gypsum would load 40,000 tons of gypsum in under three hours. This is said to be the fastest loading facility in the world for this sort of thing. They could do this twice a day. Shipments go to the States, either Jacksonville, Florida, or a place in Alabama or both. On a side note, once or twice a year - in the summer when there was no risk of the gypsum freezing in the hopper cars - about a dozen cars were loaded at one of these mines into CN open hoppers to be sent to Ontario for use in tooth paste.

The cars have two gates on the bottom of the cars, the length between the trucks. It's an air dump system that allows all the cars to be unloaded at once, as long as they have their hoses connected. There is a large long shed that cars are moved into for loading at the Mantua facility.

The 2008 Canadian Trackside Guide lists Fundy Gypsum as having two 44 tonners and three 25 tonners. Two 25 tonners have been retired for a few years and are in their junkyard (off rail on oil pads).

In the CP era before 1990, gypsum trains ran as extras. Flags were not needed after the new Canadian Rail Operating Rules were instituted in 1990.

In the CP era, a 44 tonner was used at the unloader in Hantsport. W&H had an RS-23 assigned there for a while, and most recently, a CEMR leased GP-9. The track to the unloader had a pretty sharp curve as it leaves the mainline and crosses Foundry Road, a town street.

There were also shipments by rail in CN hoppers to locations(s) in Ontario, reportedly to the interchange at CP London to deliver to Federal White Cement in Zorra, Ontario and reportedly for personal products manufacturing as well at other location(s).[8]

Gallery

Double-header gypsum train crossing the Avon River at Windsor, circa 1950. 2nd engine is no. 999.

A gypsum train near Hantsport, pre-1959.

S-3's No. 6560 & 6561 pulling plaster train near Windsor on August 28, 1956.

S-3's No. 6560 & 6561 pulling plaster train near Windsor on August 28, 1956.

Nos. 6560 & 6561 leading gypsum train passing Halifax mixed train at Windsor Water Tower on August 28, 1956.

No. 8135 wayfreight waiting for empty plaster train to pass in Windsor in August 1959. Note boxcar No. 259118.

No. 8135, No. 8133 with a train of Big Otis gypsum cars at Windsor Station, 1960.

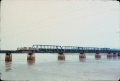

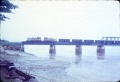

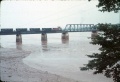

Plaster train crossing Avon River Bridge en route to quarries on July 20, 1967.

Plaster quarry train on the Avon River Bridge at Windsor, NS on July 20, 1967.

Plaster train crossing Avon River Bridge on July 20, 1967.

Tail end of plaster train crossing Avon River Bridge at Windsor on July 20, 1967.

Gypsum train westbound climbing out of Avon River Valley at Falmouth on August 17, 1977.

Gypsum train westbound climbing out of Avon River Valley outside Falmouth on August 17, 1977.

Gypsum train westbound climbing out of Avon River Valley outside Falmouth on August 17, 1977.

No. 1275 leads another locomotive and a gypsum train. Date and location unknown.

2011 to Present; The End?

On January 21, 2011 Mike Bishop, plant manager of the Canadian Gypsum Company’s Windsor plant announced that operations at the plant are “idling… indefinitely,” until the markets return. This, he says, means about 45 employees will be laid off effective Feb. 28.

The Windsor plant is spread throughout three locations. The Wentworth Road quarry, Miller Creek quarry and ship-loading operations in Hantsport will all be idle as of February 28, 2011.

In mid-November of 2011, Fundy Gypsum's parent company USG Corporation announced its intention to permanently close the operations in Hantsport, Wentworth Road and Miller's Creek.

The last train the Windsor and Hantsport Railway that served Fundy Gypsum ran was on November 2, 2010 to Windsor Junction.

References and Footnotes

- ↑ Edith Mosher, White Rock: the Story of Gypsum in Hants County Lancelot Press, Hantsport, p. 12-13

- ↑ Mosher, 10-11

- ↑ Mosher, 13

- ↑ Gary W. Ness, "DAR Vignettes: The Gypsum Unit Trains", CP Tracks, Summer 1999, Vol. 7, No. 1, page 28.

- ↑ Rebecca Titus, "Deep Brook Gypsum Plant and Storage Facility", Clements Historical Society Facebook Post May 28, 2017

- ↑ "Environmental Assessment Document for Miller's Creek Mine Extension", Canadian Gypsum Company Fundy Gypsum Plant, February 2008, p. 17

- ↑ Gary W. Ness, "DAR Vignettes: The Gypsum Unit Trains", CP Tracks, Summer 1999, Vol. 7, No. 1, p. 28.

- ↑ 8.0 8.1 Facebook DARDPI.CA group conversation Oct 31, 2021

External Links

- Men in the Mines at the Nova Scotia Archives

- Google Maps - Cars at Mantua Siding

- The Current day WHRC on CN's site.

- The WHRC at Wikipedia

- Photos of WHRC by Kim "Grizzz" Little

- Spud Roscoe's article on the marine side of the gypsum trade.

- The Sinking of the Novadoc.

- Monument to the Novadoc sailors.

- Detailed Report on shipping traffic and Hantsport loader facility.

- Windsor Gypsum Mines Mineralogy.

This category currently contains no pages or media.